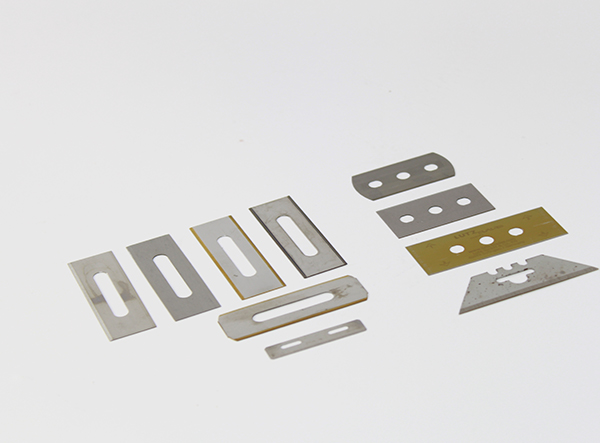

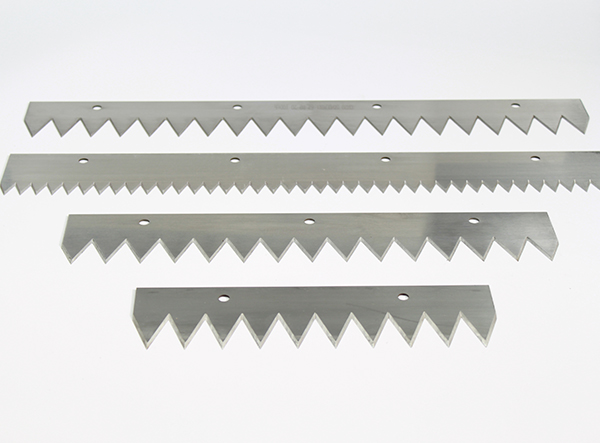

Stainless Steel, Boron coated, solid Tungsten Carbide, and solid Ceramic Zirconia.

Rowe Equipment, Inc. specializes in slitter pelletizer blades.

We take pride in furnishing the plastics processing industry high quality slitter pelletizer blades and equipment at competitive prices.

We are the leading manufacturer of slitter pelletizer blades and supplier of MRO items to the plastics industry and industrial facilities. We service plastic recycling, blown film, cast film, compounding and other industries.

We offer a complete line of replacement slitter pelletizer blades parts, including slitter pelletizer blades, for standard applications all built to the same exacting standards as the Original Equipment Manufacturer (OEM).

We are also able to custom design and manufacture slitter pelletizer blades to meet your, specialized operational requirements.

Rowe Equipment, Inc. manufactures a wide assortment of products, including slitter pelletizer blades to address virtually the entire spectrum of polymer and fiber processing operations, including the recycling, film, converter, cast film, and food industries.

We have the expertise to handle any slitter pelletizer blades needs. We are problem solvers. We match our expertise and depth of knowledge with your needs.

In order to meet your slitter pelletizer blades production schedules and minimize your downtime same day shipping is generally available.

Our experienced slitter pelletizer blades parts representatives are dedicated to your success, and efficient operation.

We are here to assist you in meeting all your specific slitter pelletizer blades needs.

Our slitter pelletizer blades customer service is second to none.

We have over 25 years of experience in melt flow, removal of gels, depth filtration, and all facets associated with the extruder upstream and downstream, including slitter pelletizer blades solutions.

In addition to slitter pelletizer blades we offer Copper Gauze, Extruder Screens, Granulator Blades, Mica Band Heaters, Cartridge Heaters, Ceramic Band Heaters, Channel Strip Heaters, Thermocouples, Pelletizer Blades, Rupture Disks, Melt Pressure Transducers, Connector Sleeves, Flexible Socks, Gaylord Covers, Drum Covers, Pneumatic Loader Filters, Shaker Screens, Flexible Hose, Tubing, Cartridge Filters, Liquid Filter Bags, Bag House Filters, Strainer Baskets, Brass Scrapers, Die Soap, and RDW Screens.

We are located near Houston Texas and supply slitter pelletizer blades globally including United States, Mexico, Canada, Germany, Uruguay, Jamaica, and Guatemala.

Contact us today for your slitter pelletizer blades needs or solutions.

Not sure your application calls for a slitter pelletizer blades solution? No problem. Let us help figure it out.

With over 25 years of slitter pelletizer blades experience, we’re confident we can satisfy your needs too!